With the exception of base metal coins like copper and aluminum, nearly all coins have been made with a combination of metals. Those metals can be nearly pure alloys or of greatly reduced purity by cladding or plating. Or not present at all.

So how do you know what’s in a coin? Most government and reputable private mints adhere to published and widely available formulas that specify the coin’s exact content and type. And while the monetary value of a government’s currency is clearly stated on the coin, its intrinsic value can be different depending on what’s in it.

It’s good to know the different ways coins can be made so you don’t end up buying something that’s not what it appears. Here’s a quick look at the three most common ways coins and other metal objects are made.

Alloys

An alloy is a combination of two or more metals that are blended together. The resulting product may be called by the name of the dominant metal—22-carat gold, for instance—or it may have a different name entirely. Brass and bronze are alloys of copper with zinc and tin, respectively. Steel is an alloy of iron.

Alloys can be used in coins for different reasons. Take gold, for example.

In its pure form, gold is very soft and wears or damages easily. To make gold coins and jewelry more durable, a small amount of another metal, usually silver or copper, is added. Jewelers use carat ratings to describe purity, but government mints always specify actual percentages of metals. Gold can also be alloyed with platinum to make “white gold.”

Alloys in US Coins

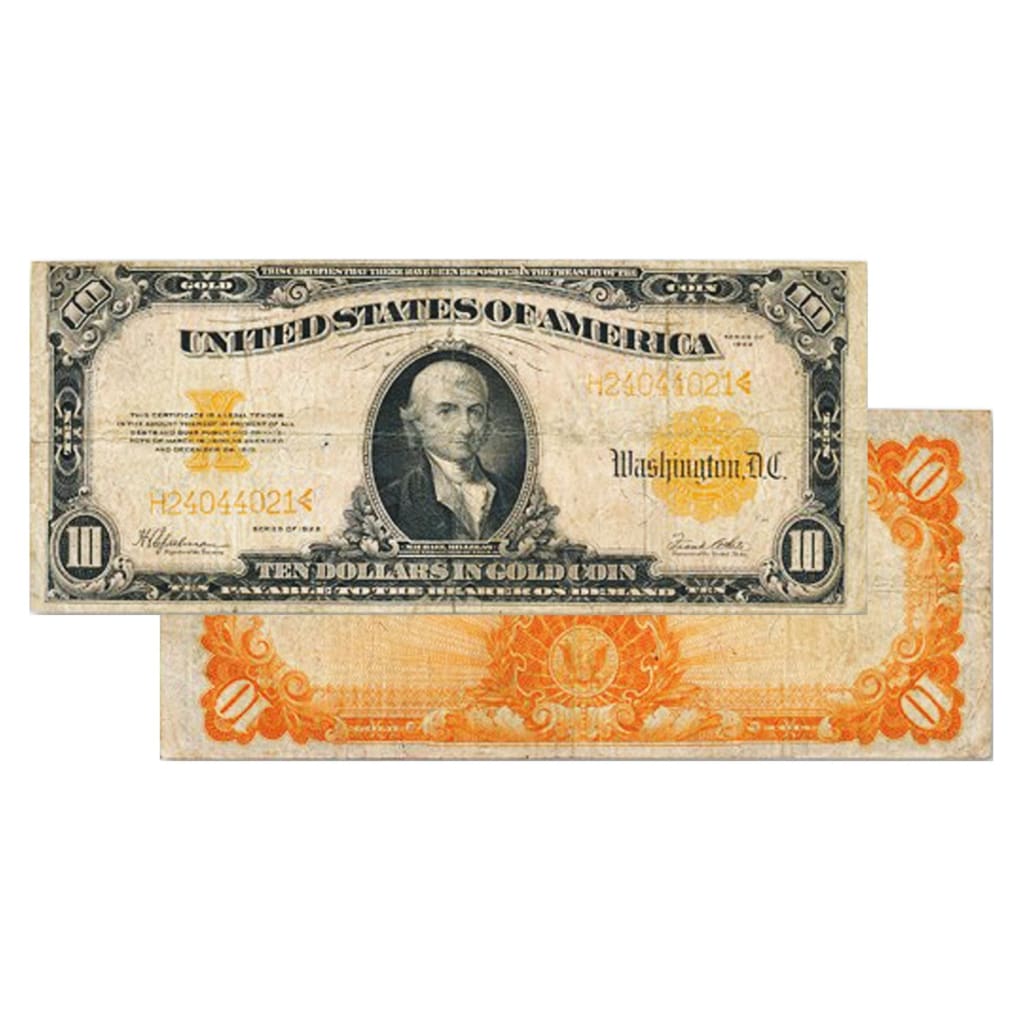

Before 1933, the US made gold coins of different denominations for circulation. Initially gold coins were set at 11 parts gold to one part silver and copper, the equivalent of 22-carat jeweler’s gold. As gold prices fluctuated, the amount of gold varied slightly, stabilizing at 90% gold and 10% copper in 1840. All silver was removed.

US silver coins were an alloy of 90% silver with copper until 1964, and nickels are a 25% nickel-75% copper alloy.

Clad Coins

Cladding is a process of applying a layer of one metal or alloy over the surface of another so that the resulting product takes on the appearance of the outer layer. Most US coins today are clad with a layer of one metal applied to both sides of another in a sandwich. The process is usually noticeable by viewing the edge of the coin, where the cladding is apparent.

Current US “silver” coins are 91.67% copper with nickel cladding.

The Sacagawea and other “gold” dollars aren’t gold at all, but a 100% copper core clad with a thin alloy of copper, zinc, magnesium, and nickel to give them a golden appearance. But they’re 88.5% copper.

Plated Coins

Plating is a process of coating an item with a thin covering of a metal. This is commonly done with costume jewelry serving ware. It’s also how US cents are made. Lincoln cents have a 97.5% zinc core with a 95% copper alloy plating resulting in a traditional copper appearance for the penny.

The Great American Coin Company offers a variety of collectable US and world coins, medals, and bullion at attractive prices. They’re just some of the many ways we serve collectors and investors around the world. Visit our website, greatamericancoincompany.com, for more information. And be sure to check back often as our selections are constantly changing.